Absolute shaft encoders, also known as shaft-angle encoders, are by no means used only to detect angular positions. They are also suitable for linear movements that can be converted into rotary movements by a toothed belt, drive pinion, or wire winch.

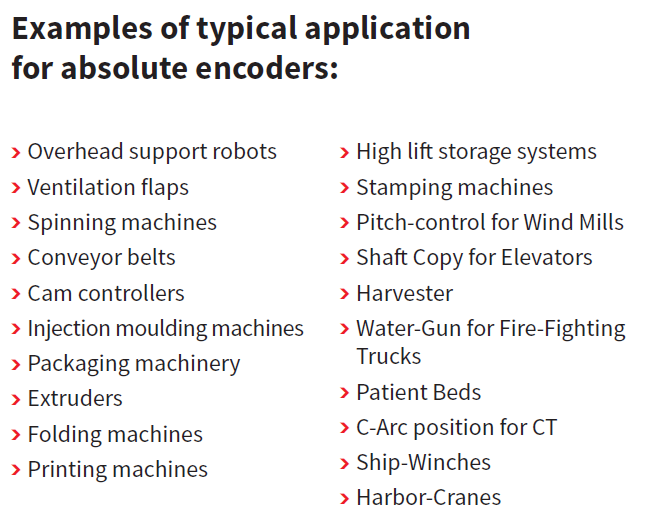

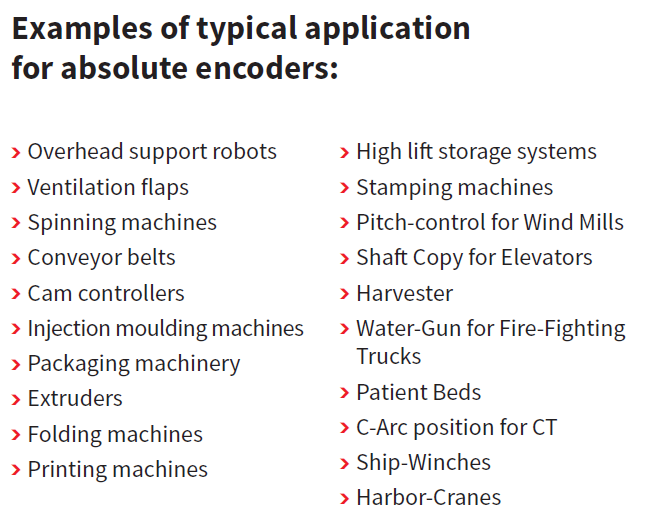

The special feature of absolute shaft encoders is that they assign a unique, digitally encoded signal to each individual measured increment. The method of transducing prevents erroneous readings, whether by a power failure, or by a transient malfunction. After the encoder is switched on again, or power is restored, the position can be read out. It is not necessary to move to a reference position, as it is for shaft encoders of the incremental type.

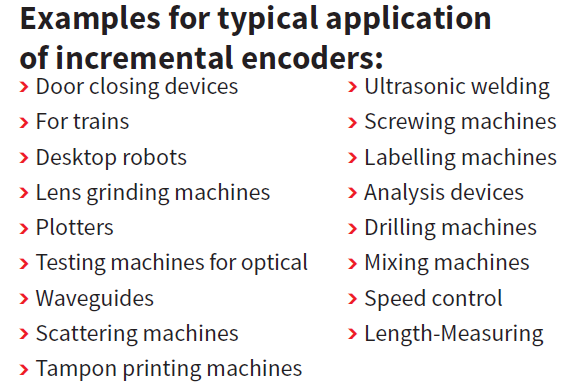

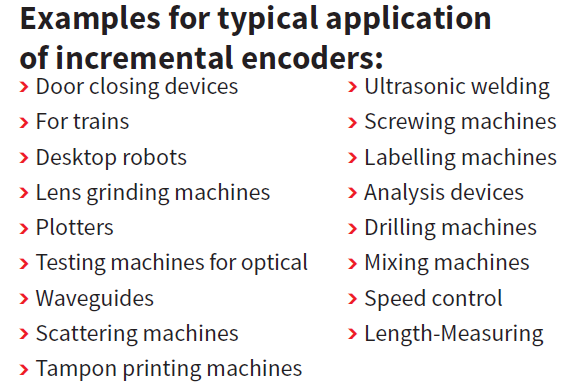

Incremental encoders are sensors capable of generating signals in response to rotary movement. In conjunction with mechanical conversion devices, such as rack-and-pinions, measuring wheels or spindles, incremental shaft encoders can also be used to measure linear movement.

The shaft encoder generates a signal for each incremental change in position. With the optical transformation, a line-coded disc made of metal, plastic or glass and positioned on a rotary bearing interrupts the infrared light ray emitted by gallium arsenid sender diode. The number of lines determines the resolution, i.e. the measuring points within a revolution. The interruptions of the light ray are sensed by the receptor element and electronically processed. The information is then made available as a rectangular signal at the encoder output.

S21/RS20 Sin/Cos Encoder, High performance encoder for elevator traction machine.We can support for Mating Connectors Shielded Cable Assemblies for RS20/S21/ERN1387 Encoder.

They are designed to survive some of the toughest environments.Paper and steel mills, aerospace applications, and food and beverage processing machinery are all areas that benefit from heavy duty encoders.Using magnetic, inductive, or specially designed optical technology, their tight sealing, heavy-duty bearings (where applicable), and high temperature range all suit them for use in harsh environments.

They are used in Following Application:

- Pulp and Paper.

- Steel.

- Oil and Gas.

- Aerospace.

- Food and Beverage.

- Off Highway Vehicle Extruders.

- Pickling and Processing Equipment.

- Paper Machines.

- Traction Motor Speed Feedback./li>

- Mud Pumps./li>

- Pipe and handling cranes.

Absolute and Incremental encoders Rated for applications in hazardous locations Ex encoders with various protection methods rated to UL,CSA,IECEx and ATEX Used in a variety of hazloc areas worldwide.

Magnetic rotary encoders are based on an inductive effect, they do not require bearings, which removes a point of failure from the system. Combined with encapsulated electronics, magnetic rotary encoders are extremely robust, can handle extreme temperatures, shock, vibration and ideal for environments with dirt, dust and oil. Dynapar offers incremental magnetic rotary encoders with up to 2,048 PPR resolution and absolute models with up to 16 bit multi-turn resolution.